Top Trends in Branded Clothing That You Required to Learn about

Top Trends in Branded Clothing That You Required to Learn about

Blog Article

A Comprehensive Guide to the Different Sorts Of Fabric Printing Techniques

Starting an exploration of cloth printing techniques exposes a remarkable crossway of custom and development. Each technique, from the careful workmanship of block printing to the quick performance of display printing, offers unique purposes and offers distinct benefits. Digital printing's flexibility and environmental consciousness stand in raw comparison to the quick customization of warmth transfer printing. Meanwhile, color sublimation printing captivates with its capacity to produce dynamic, long-lasting layouts on synthetic materials. To truly understand the subtleties and potential applications of these varied techniques, a deeper investigation is important.

Block Printing

Block Printing, one of the oldest techniques of fabric decoration, has a rich background that dates back to old human beings. The process includes carving detailed styles into wood blocks, which are after that dipped in color and pushed onto textile to develop patterns.

The accuracy and craftsmanship associated with block printing make it a labor-intensive procedure, however it also enables a high level of personalization. Craftsmens can create distinct patterns by combining different blocks or varying the application of color. This flexibility has actually added to the long-lasting popularity of block printing in both modern and standard fabric design.

Block printing is especially valued for its aesthetic qualities, including the small variants in pattern and color that arise from the hand-printing procedure. These flaws lend a distinct personality per item, identifying it from mass-produced materials. In spite of advancements in modern-day printing modern technologies, block printing continues to be a treasured technique, commemorated for its historical significance and imaginative value.

Display Printing

Display printing, one more popular textile design method, has actually transformed the market with its performance and convenience. This method includes developing a pattern, referred to as a screen, and utilizing it to use layers of ink on the printing surface. Each color in the style needs a separate screen, which permits detailed and lively multi-colored prints.

Among the key benefits of display printing is its flexibility to various sorts of fabrics, including cotton, polyester, and blends. This method is particularly suitable for large-volume orders because of its cost-effectiveness and speed. The toughness of the prints is another significant benefit, as the ink bonds well with the material, guaranteeing long-lasting layouts that stand up to multiple laundries.

The process begins with preparing the displays by covering them with a light-sensitive solution. When dried, the layout is moved onto the emulsion-coated screen utilizing a UV source of light. The revealed locations harden while the unexposed parts are gotten rid of, developing a stencil. Ink is after that pushed with the pattern onto the fabric making use of a squeegee.

Screen printing is commonly used in the fashion business, promotional products, and customized clothing. Its capability for high-grade, thorough prints secures its status as a cornerstone strategy in fabric printing.

Digital Printing

Digital printing has actually promptly arised as a cutting-edge strategy in the textile sector, leveraging advanced innovation to create high-resolution layouts directly onto textile. Unlike traditional methods, electronic printing utilizes inkjet printers to deposit pigment or dye-based inks onto fabrics, allowing elaborate and lively patterns with an amazing degree of detail and shade precision.

One of the main advantages of electronic printing is its flexibility. This approach enables on-demand printing, which significantly decreases waste and decreases stock prices. In addition, it sustains short runs and customized styles, making it suitable for limited-edition collections and bespoke projects. The removal of screens and various other configuration needs further improves effectiveness, minimizing manufacturing time and labor costs.

Furthermore, electronic printing is eco-friendly. heat transfer vinyl printing. It uses water-based inks and needs much less water and power contrasted to traditional methods, straightening with lasting techniques. The precision of digital printing likewise allows the use of a broader variety of fabrics, consisting of cotton, silk, polyester, and blends, guaranteeing adaptability across various applications

Warmth Transfer Printing

How does heat transfer printing revolutionize textile design? Warmth transfer printing involves using warm and stress to transfer a style from a specially developed paper onto material.

One of the main benefits of warmth transfer printing is its capability to generate top quality, comprehensive images quickly and successfully. It is particularly fit for little manufacturing runs and customized orders, making it a popular choice for tailored garments and marketing things. In addition, this method is versatile, fitting different types of textiles consisting of cotton, polyester, and blends.

Furthermore, heat transfer printing is reasonably economical compared to various other methods, as it requires very little setup and reduced first investment - heat transfer vinyl printing. This price, paired with its capability for producing vibrant, long lasting prints, emphasizes its essential function in contemporary material layout

Dye Sublimation Printing

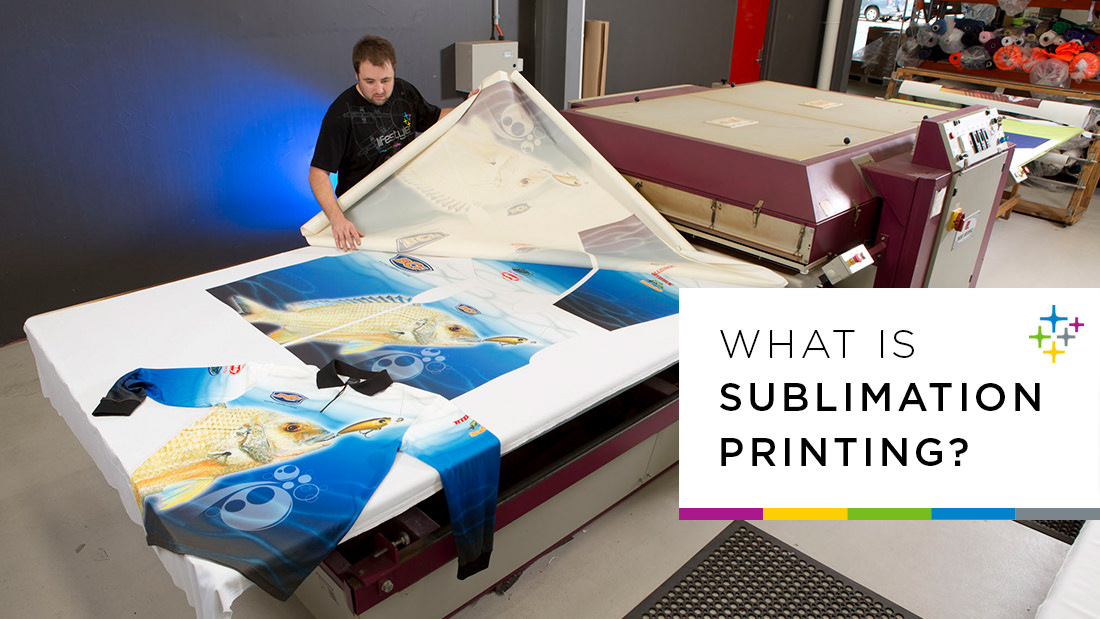

Dye sublimation printing, a sophisticated textile printing strategy, provides unequaled vibrancy and long life for designs on various synthetic fabrics. This technique involves transforming strong color right into a gas without going through a liquid state, allowing the dye to permeate the textile perfectly. The procedure begins with publishing the style onto a special transfer paper utilizing sublimation inks. The printed transfer paper is then put on the material, and both go through high heat and stress utilizing a warmth press. The warmth triggers the color to sublimate and bond with the textile fibers, developing a long-term, high-resolution print browse this site that stands up to fading and splitting.

One of the vital benefits of color sublimation printing is its capability to create continuous-tone prints with vibrant shades and elaborate information. Unlike other printing approaches, the dye comes to be part of the material rather than resting on this content top of it, resulting in a soft and breathable finish.

Conclusion

In summary, cloth printing methods each deal special advantages customized to different demands and applications. Block printing is prized for its artisanal quality, while screen printing is useful for high-volume manufacturing. Digital printing supplies convenience and ecological advantages, whereas heat transfer printing is excellent for rapid personalization. Color sublimation printing generates dazzling, resilient designs on synthetic textiles. The diversity and advancement within these methods highlight the vibrant and developing nature of the fabric printing industry.

Each approach, from the careful workmanship of block printing to the rapid performance of display printing, serves special purposes and supplies distinctive advantages. Digital printing's adaptability and environmental consciousness stand in plain comparison to the speedy customization of warm transfer printing. Regardless of advances in modern printing innovations, block printing stays a valued method, commemorated for its historical value and artistic worth.

Dye sublimation printing, an innovative material printing strategy, supplies unrivaled vibrancy and durability for YOURURL.com styles on different synthetic fabrics. Digital printing supplies convenience and ecological advantages, whereas warmth transfer printing is optimal for fast customization.

Report this page